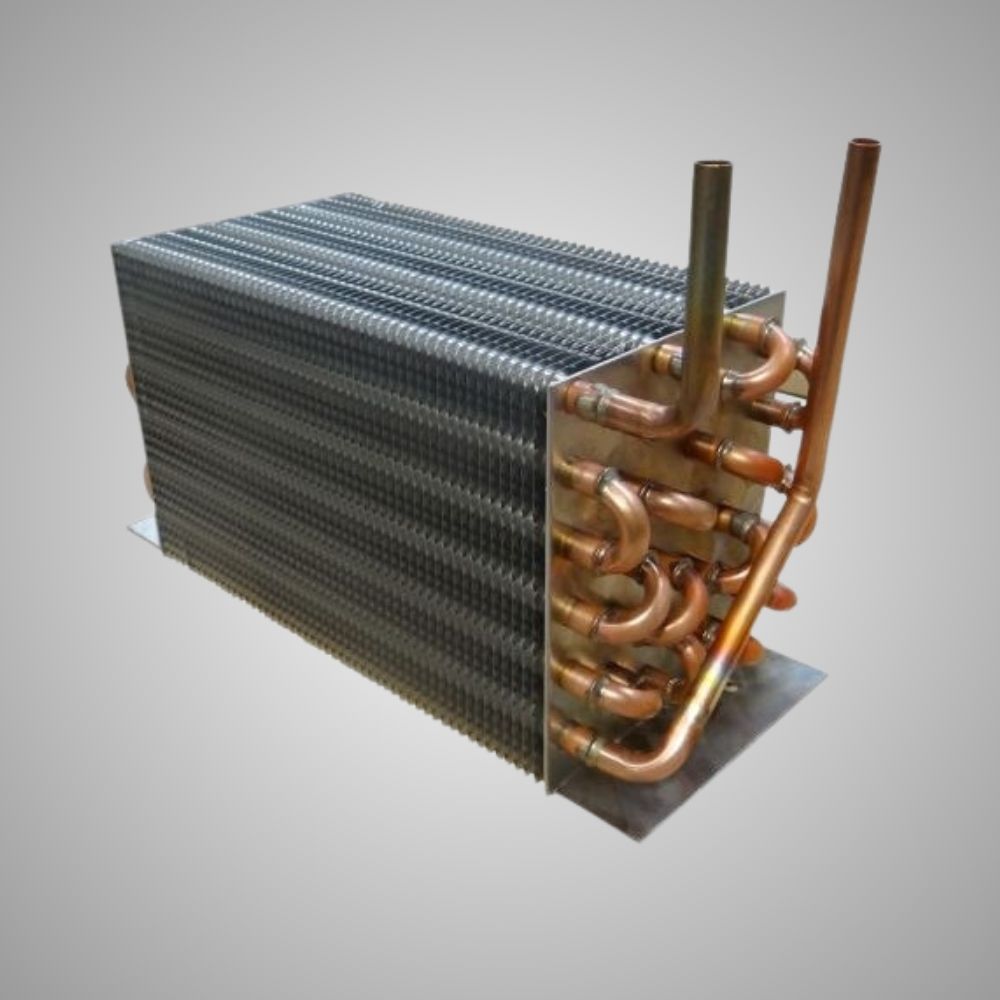

Coils

At Promont we offer coils dedicated to heating, cooling and heat recovery in various industries as well as in HVAC installations and low-carbon devices.

We manufacture:

|

|

CERTIFICATES: AHRI, PZH, TM65

.jpg) |

.jpg) |

| . | . |

| call us | download the catalog |

COILS PRODUCED IN EU (POLAND)

PROMONT has been providing solutions for air conditioning, ventilation, heating and cooling (HVAC) systems, including THERMAL COILS, for over 30 years. Many years of experience in the industry and the development of modern technologies have enabled us to mean that our products are fully adapted to your needs and are always characterized by the highest quality and attention to detail. Our wide range of fin spacing and tube diameters in the heat exchangers we manufacture, means they are used in wide variety of applications, such as, heating, cooling, condensation, and evaporation.

Manufactured in Poland, our well-trained design team ensures the product selections provide clients with very best solutions leading to cost, material and carbon savings. Depending on the intended use, we can manufacture coils differing in design, construction, material and operating principle.

We are an ISO compliant manufacturer and all our products are subjected to quality assurance procedures through appropriate leak tests to ensure safety of use and high quality of products.

Should clients wish to undertake selection of heat exchangers independently they are welcome to use our catalogue sheets and submit any enquiries via email, where our skilled and helpful team can review and discuss any requirements to offer the perfect solution. |

|

|

Offered types of fins:

- aluminium: standard exchangers (water, steam, evaporators, condensers);

- epoxidized aluminium: used in exchangers operating in conditions of increased corrosiveness of aluminium, e.g. evaporators of refrigerated counters;

- magnesium aluminium: increased resistance, marine conditions, slightly alkaline environments;

- copper: increased alkali resistance, typically used in the mining industry.

For applications involving aggressive environments, we offer additional coating of our heat exchangers: painting or cataphoresis.

The carbon footprint of our products is important to us, which is why we are committed to using recycled materials wherever possible.

Application of finned heat exchangers:

|

|